Industrial Steam Cleaning

Industrial steam cleaning is an entirely different process from hot water pressure washing. Water in an industrial steam cleaning machine is heated up to 320°F (160°C) at a low pressure up to 250 PSI (17.24 BAR). The commercial steam cleaning equipment uses steam’s expansion to accelerate water droplets, at the boiling point, to a high velocity out of a specialized steam cleaning nozzle. Unlike a pressure washer nozzle, the steam cleaning nozzle has an expansion zone placed past the pressure orifice, which directs the water vapor energy to a smaller area, instead of dissipating in all directions. The tremendous expansion is directed by the conical steam nozzle, accelerating the water droplets. The expansion nozzle's effect can be compared to that of the choke of a shotgun. Not only does the expansion nozzle direct the steam cleaner's output, but it also serves as a propulsion chamber. The closer the steam cleaner's nozzle is to the surface to be cleaned, the higher the temperature and velocity of the water/steam mixture, and the more rapid the cleaning action. For many cleaning applications, the nozzle should be held close to the soiled surface to achieve the best results.

Read more about the benefits of using steam in our Why Steam? paper.

All-electric industrial steam cleaners use electric immersion elements to heat water up to 320°F (160°C) saturated steam with no fumes or exhaust.

Electric Heated

The Dakota II line of fuel fired steam cleaners provide up to 320°F (160°C) saturated steam at the nozzle which produces up to 333% more cleaning impact…

Fuel Fired

The SafeSteam™ steam cleaner lets you use your plant's internal steam as a powerful steam cleaning tool!

Safesteam

I can't tell you how happy we are with our purchase of the steam cleaner from Sioux Corporation. This steam cleaner uses less water, lessening, even more, the chance of moisture accumulating in the electronic areas deterring mechanical issues. We have noticed also in addition to using less water, we have not given up any cleaning capabilities at all. As a matter of fact, I will tell you that the equipment is much cleaner than before and more than exceeds my expectations. We can use it on all the large and small equipment, floors, walls, and walk-in cooler with minimal effort. I feel by using this steam cleaner we picked up some extra points on our latest sanitation audit! Again, we are very pleased with your product, and the job it does. Thank you again for your help in assisting us with our cleaning needs. Food Company - Louisiana

Typical Applications for an Industrial Steam Cleaner

- Cleaning engines, transmissions, drive trains, and other equipment prior to performing service and maintenance work.

- Thawing frozen drains, tanks, piping systems, culverts, etc., for street and highway departments, manufacturing and processing plants, pipelines, and other industries.

- Removing chewing gum from sidewalks, tables, stadiums, entryways, etc.

- Preparing surfaces for painting, especially removal of cutting oils, grease, and similar oily or greasy substances.

- Degreasing dies and tools in manufacturing operations.

- Removing fats, grease, oils, and substances from surfaces and equipment in food processing plants.

- Melting and removing paraffin and wax or grease from traps and drains in wastewater treatment plants, petroleum refineries, and for similar use in other industries.

- Cleaning and restoring brick, block, stone and other masonry surfaces for maintenance or restoration projects, at monuments, cemeteries, and similar applications, where steam is more gentle and less intrusive and damaging than high pressure cleaning.

- Wide range of other specialty applications.

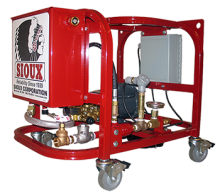

Sioux offers a full line of industrial steam cleaners, and all are engineered for optimum performance and reliability in the most demanding environments.

- Electrically Heated Steam Cleaners - All models require 3 phase electrical power - Includes Explosion Proof models

- Fuel Fired Steam Cleaners - Heated with Oil (Diesel), Natural Gas, or LP fired burner

- Safe Steam Units that Utilize Your Existing In Plant High Pressure Steam

Have a Question?

Sioux serves a wide range of industries with our decades of experience, reliable products, and value added services that help companies every day around the world.

Why Sioux?

Sioux's products are built for the concrete, petroleum, mining, rail, greenhouse, food & beverage, and manufacturing industries with the highest quality and durability in mind. We strive to make sure our customers have the safest and most efficient equipment they can rely on year after year.